Making Roman concrete produces as much CO2 as modern concrete

Builders in ancient Rome used a special kind of ancient concrete to construct their aqueducts, bridges, and buildings. But is Roman concrete more sustainable than the Portland cement used in today's concrete? The answer is more nuanced than one might think, according to a new paper published in the journal iScience. Roman concrete produces as much CO2 as modern methods, but fewer air pollutants.

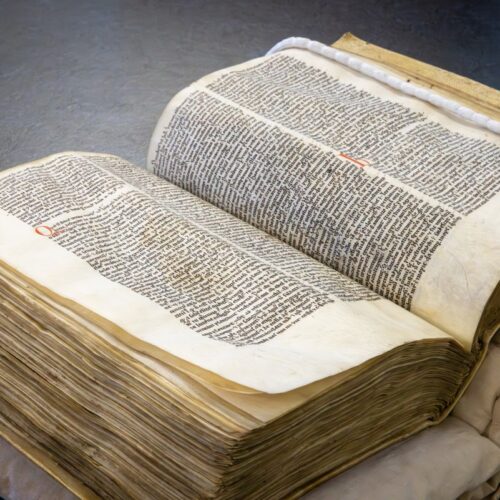

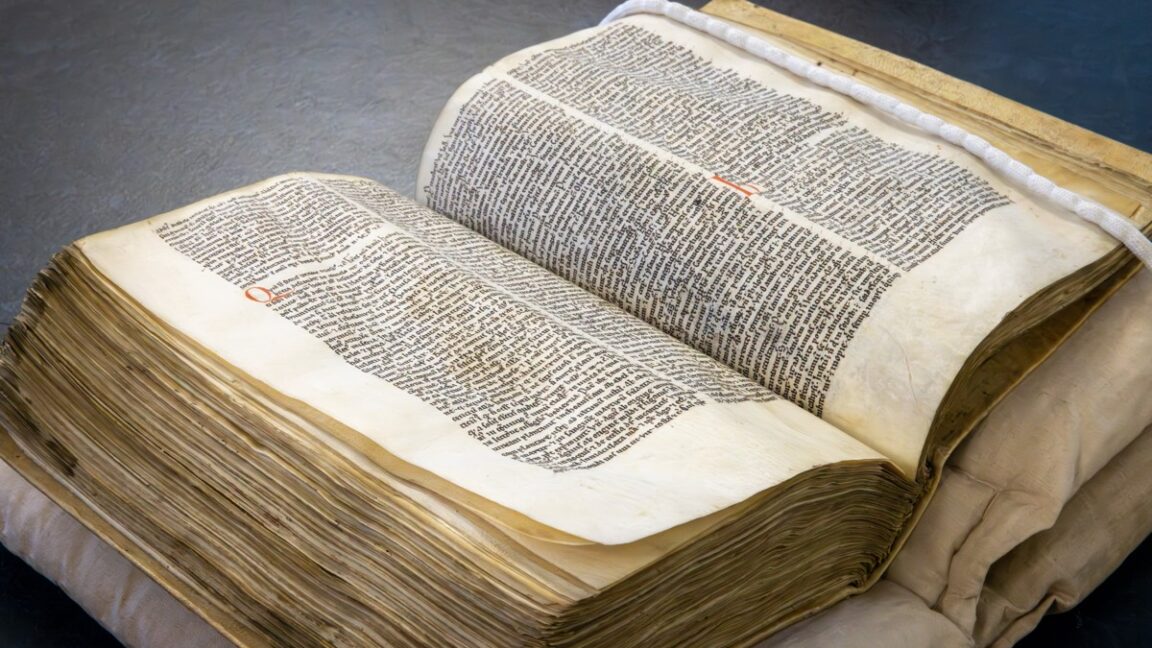

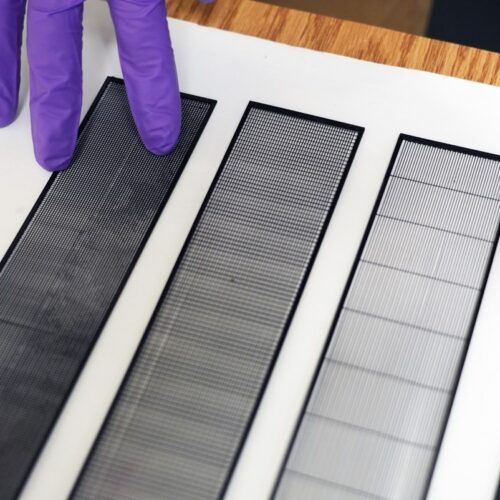

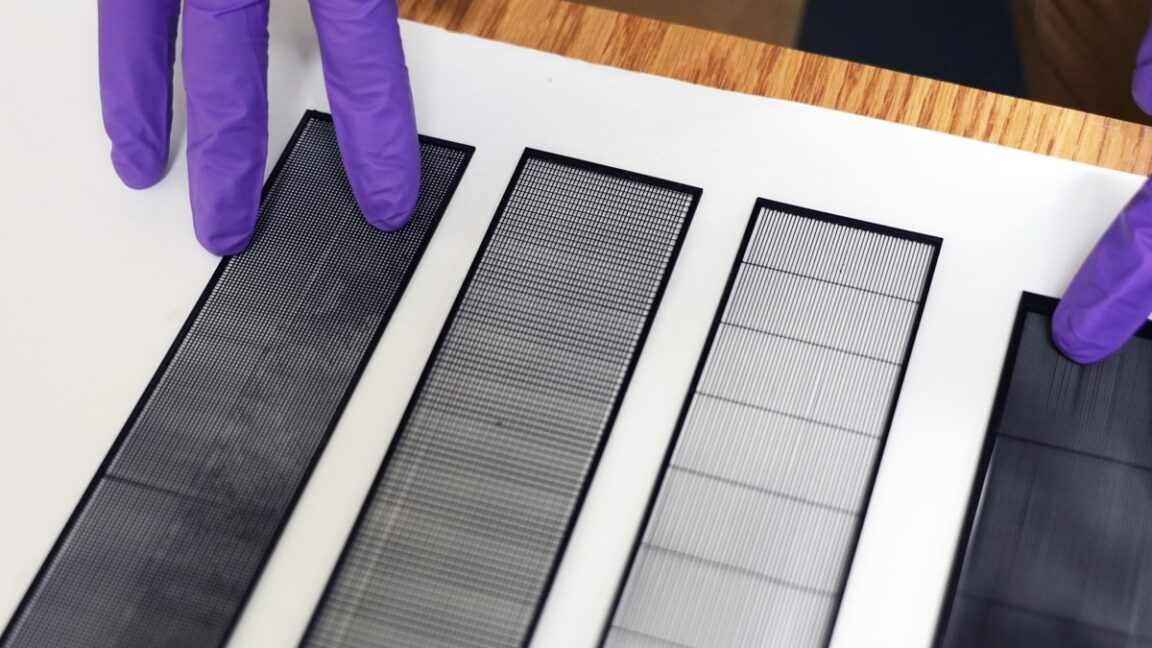

As we've reported previously, like today's Portland cement (a basic ingredient of modern concrete), ancient Roman concrete was basically a mix of a semi-liquid mortar and aggregate. Portland cement is typically made by heating limestone and clay (as well as sandstone, ash, chalk, and iron) in a kiln. The resulting clinker is then ground into a fine powder, with just a touch of added gypsum—the better to achieve a smooth, flat surface. But the aggregate used to make Roman concrete was made up of fist-sized pieces of stone or bricks.

Scientists have long been fascinated by the remarkable longevity of Roman concrete; it's a very active field of study. For instance, in 2017, scientists analyzed the concrete from the ruins of sea walls along Italy's Mediterranean coast, which have stood for two millennia despite the harsh marine environment. That analysis revealed that the recipe involved a combination of rare crystals and a porous mineral. So exposure to seawater generated chemical reactions inside the concrete, causing aluminum tobermorite crystals to form out of phillipsite, a common mineral found in volcanic ash. The crystals bound to the rocks, preventing the formation and propagation of cracks that would have otherwise weakened the structures.

© James Cocks/CC BY-SA 3.0